loading...

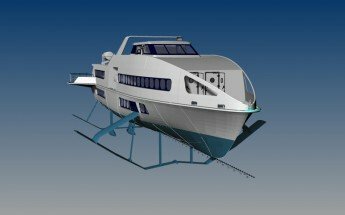

Computer Numerical Control machines, in order to obtain a perfect control of the foils geometry and high structural strength while reducing maintenance during life cycle. The hull, made of aluminum alloy, is entirely welded, in place of the old studded systems, in order to reduce friction during take-off for the benefit of consumption.

The mufflers for engines exhaust provide a high noise attenuation without compromising performance.

The sound reduction is approximately 25db. The greater chine beam in the stern body allowes an increase of the available space giving passengers a more comfortable accommodation. The side doors without a central pillar do not provide any obstacle, and therefore the evacuation of passengers is faster. The increased space in the maneuver positions of bow and stern, provides an improvement in the working conditions and a faster of intervention. The rafts are placed on the main deck to lower the centre of gravity thus providing greater comfort and less stress on the stabilization system.

The cavitation effects of the propellers have been minimised, as a result of an attentive hydrodynamic study, identify a new wing profile, thus achieving a reduction of rolling resistance, resulting in reduced fuel consumption at service speed.

The skill and knowledge at Liberty Shipyard, the only shipyard in the world specializing in the cons...

Work continues on the construction of what we can already call "the flagship" of the HSC Shipyard: t...

22/07/2015

Work continues on the construction of what we can already call "the flagship" of the HSC Shipyard: the ADMIRAL 350.

read more

20/02/2014

His name is Carlo Morace the last hydrofoil joined our fleet!

read more